CNC lathes, or Computer Numerical Control lathes are nothing short of a miracle and work in allowing us to keep making parts. This is due to the machines that can be programmed with pinpoint accuracy to mill pieces at nearly perfect speeds. CNC lathes are computer powered machines that have transformed the production of parts in various industries.

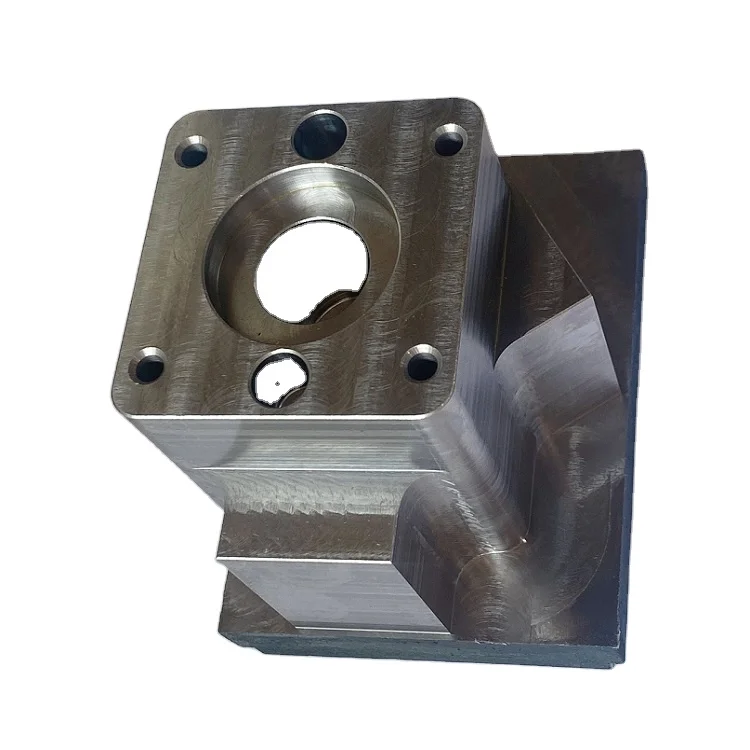

CNC lathes are versatile in the true sense of that term - they can make products from airplanes and cars to medical devices. It is the ultimate machines for manufacturing necessary parts such as gears, shafts and bushings that are very important in complex mechanical systems. This diversity in needs also makes apparent the value of CNC lathes in modern manufacturing.

First and Foremost CNC lathe technology can heavily produce components quickly parts for precision machining. Yes, the traditional lathes which needed a more of manual work and human force, in contrast to CNC lathes produce many number on parts with less time instead this make overall cost reduction for businesses. In addition, the automatic nature of CNC lathes reduces the probability for human error to occur enabling each component manufactured with accuracy and repeatability.

In a world of innovations on the CNC lathe technology. Whereas, the other breakthrough is with "live tooling" which allows a lathe to cut parts while they are still in their mounted position in the machine. This development gets rid of all the removal and reinstallation work, which would greatly facilitate mass production. The advent of 'multi-axis machining' has furthermore increased capabilities, permitting movements in several directions now with CNC lathes that the manufacturing process can produce even more complex components than before especially advantageous when making very precise medical devices.

Ultimate guide to choose the Perfect Machine for your Business

Selecting a CNC lathe for your business is no small investment and one that should not be taken lightly. Size of the Machine - The primary thing that matters is to know what size you need your machine based on how large are parts being produced. Second, determining the capabilities of the machine such as live tooling and multi-axis machining are critical to meeting your unique production needs. Finally, it is only by choosing a quality and reliable brand name that we can guarantee our machinery will offer the maximum performance in any tooling work for this CNC lathe.

The said transformation can be conclusively attributed to the integration of CNC lathes into manufacturing processes. These machines improve process from a speed, accuracy and consistency point of view, which in place allow businesses to function more efficiently and competitive. CNC lathes, furthermore in their ability to construct more complex parts also had indirectly lead the way for product innovation and development allowing higher marketable value spurring advancements through out various industries. While there are unlimited possibilities for further technological advancements in the field of CNC lathe technology, the future will be bright as long as manufacturing sees continued growth and evolution.

We have a highly skilled purchasing team as well as a cnc lathe pool of standard parts. We also outsource surface treatment and heat treatments.

More than 14 years of cnc lathe in processing and a complete machine tool, including CNC milling, CNC lathe, grinding machine, EDM and wire cutting etc. We have an benefit for products that are multi-process.

Complete quality control is achieved by full involvement. From the very beginning, quality prevention to the final product, we follow a strict quality control process. The product testing is divided into raw material testing, the testing of processing and finally testing. Our testing equipment is also very cnc lathe, the main equipment comprises CMM altimeter, projector, hardness tester, spectrometer, and other such equipment. We are a partner with a lot of domestic and foreign-funded companies. We also have passed through their different layers of audits.

We have experienced design engineers to cnc lathe our technology. Our designers are experienced in mechanical design. Some of our designers have more that 20 years experience in the field of design. They have been involved in process improvement and fixtures, as well as equipment design and much more.