Die cutting is an interesting process that uses a special tool called die to slice materials accurately into particular forms - in essence, super-powered cookie-cutters. This is a precision device that provides for precise and accurate cuts (most often made of metal). Aitemoss die cut parts is an essential operation in the manufacturing sector, across industries like automotive electronics or packaging.

Advances in die cutting technology have introduced new techniques for producing custom cut parts with improved accuracy. Provided in ultra-modern processes that make the Aitemoss die cutting products able to be utilized for complex geometries with liberal tolerances suitable for mass scale production.

Making Things the Same Size

The Key One Of The Advantages of Die Cut Parts Is - Size And Shape Equality. Such uniformity is tremendously useful in many manufacturing applications because those final components all come together and just work. In addition, Aitemoss custom die cut parts is an efficient method for manufacturing parts; thus product costs remain low.

New State of the Art Die-Cutting Technology

With the rise of die-cut parts, manufacturers have developed new ways to improve processes and reduce waste. Digital cutting is one way to accomplish this, using a digital-controlled machine that automates the cutting process through computer technology.

Laser cutting is a new revolutionary technology in die cutting that uses advanced high powered lasers to cut materials into distinct shapes. It works quite well for thin cuts, or when using thinner materials.

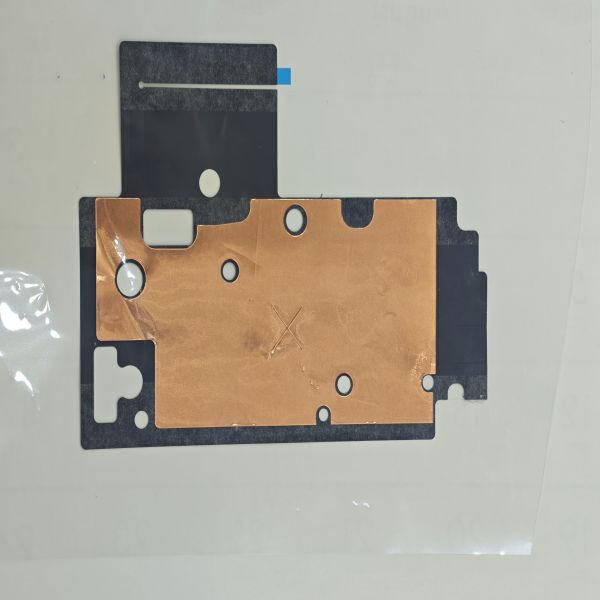

Die-cut components solve problems in a wide range of industries with specific needs within their respective products Die-cut gaskets are used to stop leaks between different parts, like in the automotive sector. They are engineered to be used in high temperature, pressure load and environmental applications particularly suited in heavy duty aerospace and defense industries.

Die-cut parts reflect a lot about the final product's quality. These products are defect free as it has been manufactured through precise cutting and confirming to industrial norms. Die-cut parts are commonly employed in the packaging sector to fabricate customized packs that will fit snugly around products, guaranteeing their safety during shipment.

The Die Cut Rolls of Industrial Change

The cut is of commercially significant quality because die cutting offers a more quick and accurate method for producing cuts on non-standard materials. This line of innovation has reduced material weight, increased part improved quality and eliminated paper die-cut waste production as a result to the introduction of new innovative processes for producing die-cut parts.

With the ongoing advancement of technology die-cutting methods will continue to evolve, with greater production capacities as well as new applications being uncovered across a wide spectrum of industries.

We have experienced design engineers to Die-cutting parts our technology. Our designers are experienced in mechanical design. Some of our designers have more that 20 years experience in the field of design. They have been involved in process improvement and fixtures, as well as equipment design and much more.

Total quality management is achieved through participation in Die-cutting parts. From the early quality prevention to the more advanced product, it is a stringent quality control process. Testing of the product is split between raw material testing, the testing of processing and finally testing. Our equipment for testing is very complete, the main equipment includes CMM projector, altimeter and hardness tester, spectrometer and many more. We work with a variety of domestic and foreign-funded companies. We also have passed through their different layers of audits.

We have a highly skilled Die-cutting parts team as well as a huge source pool of parts that are standard. We also outsource surface treatment and heat treatments.

We Die-cutting parts more than 14 years of experience as well as machining equipment that is complete which includes CNC milling grinding machine, CNC lathe EDM and wire cutting etc. Multi-process machines are our specialty.