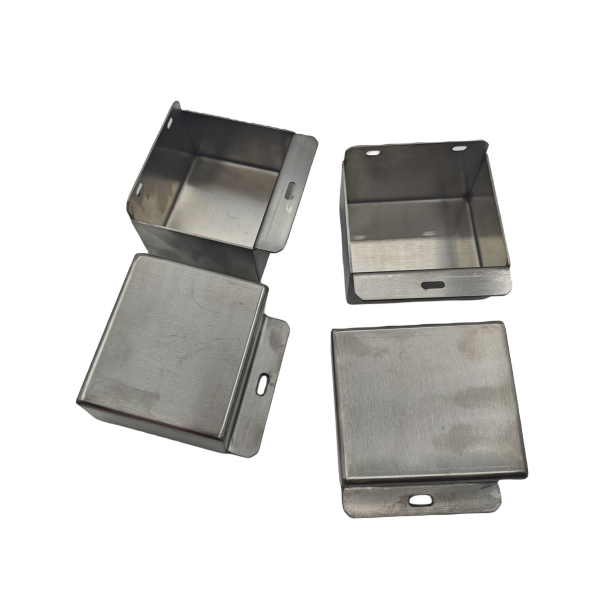

Have you ever wondered how metal parts so unique can be made? These are machined to exact machine or object fit. Today we are going to discuss the realm of custom metal parts, and how they get manufactured. At the end of which, you will also realize why these articulated parts are integrated into many different models and industries.

Needless to say, the sector in which we operate is one that requires very detailed work when talking about manufacturing custom metal parts. This precision means that all parts have to be machined so perfectly, so they fit together correctly the first time. We use special tools and machines to do this cutting with accuracy. They help us make sure each part is the right size and shape. Parts would not function correctly, due to their lack of precision, and that could interfere with the machine for which it was made.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

НЕ

НЕ

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

CA

CA

TL

TL

ID

ID

LT

LT

UK

UK

VI

VI

SQ

SQ

HU

HU

MT

MT

TH

TH

TR

TR

MS

MS

GA

GA

CY

CY

IS

IS

BN

BN

MN

MN

MY

MY

UZ

UZ