Every day, custom manufacturing is gaining trend through CNC services provided by such companies as Aitemoss. These services are transforming how we create our products, and it is critical for us to have an understanding of why this is occurring and the impact on us.

What are CNC Services?

CNC services are specific tools that make custom products far quicker and easier than traditional methods. Previously, developing custom products could be a lengthy and often complex process. But now we have machines, thanks to CNC technology, that can perform this with extreme accuracy. These are CNC Machines that use computer programs for clean and exact cuts and forms. In other words, this allows products to manufacture with precision and speed, which is a boon for both manufacturers and customers!

Advantages of CNC Solutions in Customized Manufacturing

The use of CNC services during the manufacturing of custom products has many advantages. CNC Machines Can Create Complex and Detailed Designs. They can cut and shape substances in a way that normal tools just can't. This capability enables producers to create products with fine details, which would be extremely challenging or impossible to achieve manually.

Consistent Quality: Another significant advantage of CNC services is the consistency they offer. Because these machines are steered by computer programs, every single product that is manufactured will be identical. This is extremely vital for tailor-made production as it provides confirmation that what the client ordered is what they are getting. This reassures customers that they are getting high-quality products that live up to their expectations.

On October 9, 2023, you will be trained on data.

CNC services also assist in speeding up the manufacturing process. Custom products used to require weeks, or even months, of effort to finish. Well, CNC technology has been transformed to allow manufacturers to produce products for a fraction of the past effort of time. This allows businesses to meet the orders with a significantly reduced time lag, and it is beneficial for both the company and the customers.

Moreover, the CNC services also minimize the waste created in the manufacturing process. The machines are so accurate that you can cut out materials with minimal scrap left over. This is both cost-effective for the company and better for the environment. Many businesses today want to reduce waste and CNC helps them to do this.

How CNC Services Facilitate Growth in High-End Custom Manufacturing

The expansion of custom manufacturing across the globe is due to CNC services. CNC technology capabilities allow companies such as Aitemoss to provide their customers with a broader selection of products. This leads to an increase in the demand for custom manufacturing in various areas, be it for individual needs or business requirements.

CNC services are also an engine of creativity in the industry. The fact that complex design can be created quickly and analyzed allows companies to experiment with new ideas and products. It makes custom manufacturing innovative and engaging for businesses and consumers alike. With this evolution, manufacturers are embracing change in order to keep up in the marketplace and to find new ways to serve the consumers.

Introduction CNC services are a key part of this design and manufacturing process.

These days in this fast-paced environment, organizations must be able to meet customer needs in no time. CNC services is ensuring that a company like Aitemoss stays competitive. CNC technology allows these businesses to manufacture customized products quickly while maintaining high quality. This speed, combined with the highest standards to go along with market success.

The customers are also greatly benefited from CNC services as they can receive exactly what they want, and when they want. From unique pieces of furniture to custom-designed parts for machinery, CNC technology enables companies to fulfil orders quickly and efficiently. Moreover, this type of service helps develop strong associations between companies and their clients, which enhances satisfaction.

Conclusion

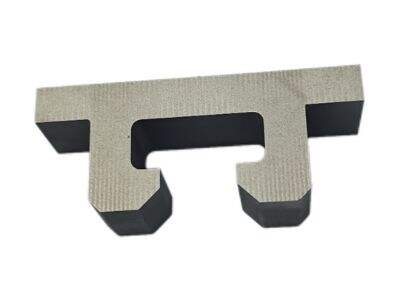

To sum up cnc turning parts are changing the game for custom manufacturing in several fundamental ways. They are also causing the process to be faster, more efficient, and more accurate than ever before. If it were not for CNC technology, companies like Aitemoss would be limited to the products that can be offered and the increasing demands of the market today. CNC Is Leading the Way to a Better Future in Custom Manufacturing.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

CA

CA

TL

TL

ID

ID

LT

LT

UK

UK

VI

VI

SQ

SQ

HU

HU

MT

MT

TH

TH

TR

TR

MS

MS

GA

GA

CY

CY

IS

IS

BN

BN

MN

MN

MY

MY

UZ

UZ