Když se ozve slovo mlýning, pravděpodobně vám napadne první věc, kterou budete dělat, je mlýning mouky nebo kukuřice pro jídlo. Existuje však jedinečný stroj, který dokáže řezat složité tvary do kovu a dalších materiálů. Toto je CNC frézovací stroj, který je v podstatě řízen počítači, aby umožnil výrobu neuvěřitelně malých a přesných dílů.

CNC je zkratka pro Computer Numerical Control. Počítače řídí stroji, co mají dělat. Program řekne stroji, jak rychle se má pohybovat, kde řezat a jaký tvar musí mít. U pevné frézovací soupravy je tohoto druhu přijímá více detailů o stabilní frézovací výbavišnu (osobu), která se používá, a stojí mnohem méně než při použití běžné frézovací soupravy, kterou je třeba ovládat ručně. Takže, možná CNC Frézování - počítač dělá většinu práce a udělalo to MNOHEŽNÁČ snadší.

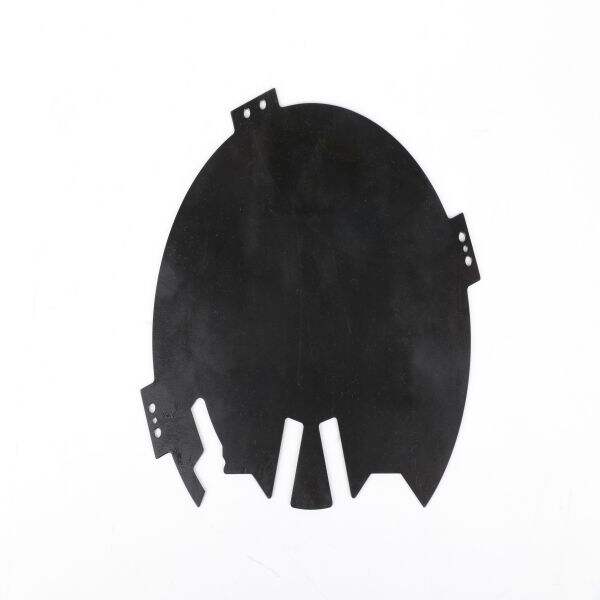

Když použijete CNC frézování, naopak, lze vytvářet díly se složitějšími tvarovanými tvary, jako jsou křivky a úhly. Stroj mohl také pohybovat ve třech různých směrech, nahoru a dolů, vedle strany k straně kombinované s předním a zadním směrem. Typická frézovací stroj posouvá pouze ve dvou směrech, takže 3D tvary, které dokáže vyřezat, jsou nějak omezeny jejich rozsahem x a y-ové osy. Proto může být lepší vyrábět komplexní návrhy pomocí CNC frézování.

Nevšechny součásti by musely být identické, ale pokud jde o výrobu součástí, je přesnost klíčová. Pokud nemají komponenty vhodné tolerance, mohou se špatně zapadat nebo vést ke znehodnocenému konečnému produktu. CNC frézování je jedním z přesnějších procesů pro výrobu součásti, protože používá počítačové programy k řízení stroje. To také znamená, že všechny řezy jsou přesné a pečlivě promyšlené.

Poté existuje také koncept tolerance pro výrobu dílů. Tolerance je maximální rozdíl ve velikosti dvou součástí, který je stále přijatelný. To jednoduše znamená, že pokud musí být součást 2 palce, může být přijatelné, aby velikost součásti byla o trochu kratší nebo delší, tedy mezi 1,999 palcem a 0,001 palec. Tento rozdíl se nazývá tolerance a ukazuje přesnost měření.

Vzhledem k tomu, že stroj pracuje prostřednictvím počítačových procesů, je každá součást vyrobená konzistentně s minimálním množstvím odchylek. U člověka závisíte na šanci, že chyba nastane mnohem častěji, než je nutné. To znamená, že součásti budou mít velmi vysokou kvalitu a budou fungovat tak, jak je potřeba, což ve většině případů musí nastat.

Ať už máte díl, který je nemožné najít, nebo potřebujete jen jeden určený díl, CNC frézování je vynikající volbou. CNC frézování vyrábí kusy na zakázku, které přesně popíšete podle příležitosti. Může to být něco rovného vpřed, jako je nosítka, která drží dvě věci na místě, nebo může být raketová věda, která vyžaduje nejen držet všechno na místě, ale také velmi přesný tvar, jako je například rotorová čepele pro vrtulník.

Máme zkušené konstruktéry inženýry pro přesné CNC frézování naší technologie. Naši navrhovatelé mají zkušenosti v oblasti mechanického návrhu. Někteří z nich mají více než 20 let zkušeností v oblasti návrhu. Byli zapojeni do vylepšování procesů a návrhu držáků, stejně jako do návrhu zařízení a mnohem více.

Kromě automatizovaného a strojírenského zařízení máme také profesionální nákupní tým a velkou zdrojovou bázi dodavatelů pro standardní součásti, stejně jako externalizované povrchové zpracování a tepelnou úpravu.

Více než 14 let zkušeností s přesným CNC frézováním a kompletním výbavem na strojení, který zahrnuje CNC frézovací šlechtačku, CNC točnou, EDM, drátové řezání a další. Jsme jedinou společností, která nabízí významnou výhodu pro produkty vyžadující více procesů.

Celkové řízení kvality je dosaženo plným zapojením. Od rané prevence kvality až po konečný produkt, jedná se o přísný systém kvality. Testy produktu jsou rozděleny na testy surovin, testování procesů a testování konečného produktu. Náš výkon testovacích zařízení je rozsáhlý, hlavní vybavení zahrnuje CMM, projektory, výškoměry, tvrdostníky, spektrometry a mnoho dalšího. Spolupracujeme s několika zahraničními a americkými společnostmi. Společnost také prošla jejich různými přesnými CNC frézovacími procesy.