Der er mange varer fremstillet af fabrikker. Det er som at lave småkager! Selvfølgelig ville de fleste mennesker sætte en masse cookies i stedet for kun 1 eller to som eksemplet, men uden at tælle det så klart nemmere at glemme over tid. Det er lige så vigtigt at være økonomisk, da bagning i løs vægt sparer tid, penge og energi; en tredobbelt sejr.

OEM-ledere, der bruger disse dele, høster store fordele, og det samme gør deres fabrikker. CNC Dette er et virkelig teknisk udtryk, som betyder, at man skal bygge maskiner med sæbe bortset fra computere og fortæller andre computere, hvordan man laver ting. Fabrikker, der kan fremstille ting med minimale fejl på kortere tid, er gavnlige. Disse maskiner er dybest set ubrugelige uden en eller anden form for computere til at kontrollere deres funktionalitet, så de alle arbejder i synkronisering med hinanden. Sådan kan fabrikker bare få fat i alle de ting og lave endnu flere ting så hurtigt sammenlignet med at få folk til at gøre det, hvilket selvfølgelig gør en kæmpe forskel, når de prøver at få tingene gjort!

Fabrikker får hurtigere, hvad de vil have, med mindre materiale ved at overbevise dem om at OEM CNC-dele. De er lavet af få ressourcer, hvilket er meget godt for vores planet. Perfekt for virksomheder til at lave flere ting, de kan sælge.

Og alle disse maskiner ville være underlagt begrænsningerne af elektroniske (eller pneumatiske) kontroller, manipulation og vedligeholdelse eller worst case scenario: menneskelig indgriben. Tænk bare på, hvor længe du kunne sidde og stirre på din legetøjsrobot for at sikre, at alt går glat! Det ville være trættende. Dette bliver erstattet af CNC, fordi computeren gør alt dette selv og dermed også forårsager færre fejl. Derfor er producenter i stand til at skabe meget mere på én gang i en OEM CNC-komponent

Bare en lidt: Ved du, at planter kan dyrke skræddersyede komponenter på bestilling? Det er rigtigt! Et godt eksempel på dette kunne være, at du sammensætter dit eget legetøj, men det har brug for et stykke, der vil fungere og køre inde i robotten; produceret efter fabriksspecifikationer. Derudover kan de fremstille gravering og tilpassede dele til forskellige applikationer i CNC. Det betyder, at uanset hvad du bygger, er der en måde at få tingene til at passe perfekt. Er det ikke fantastisk?

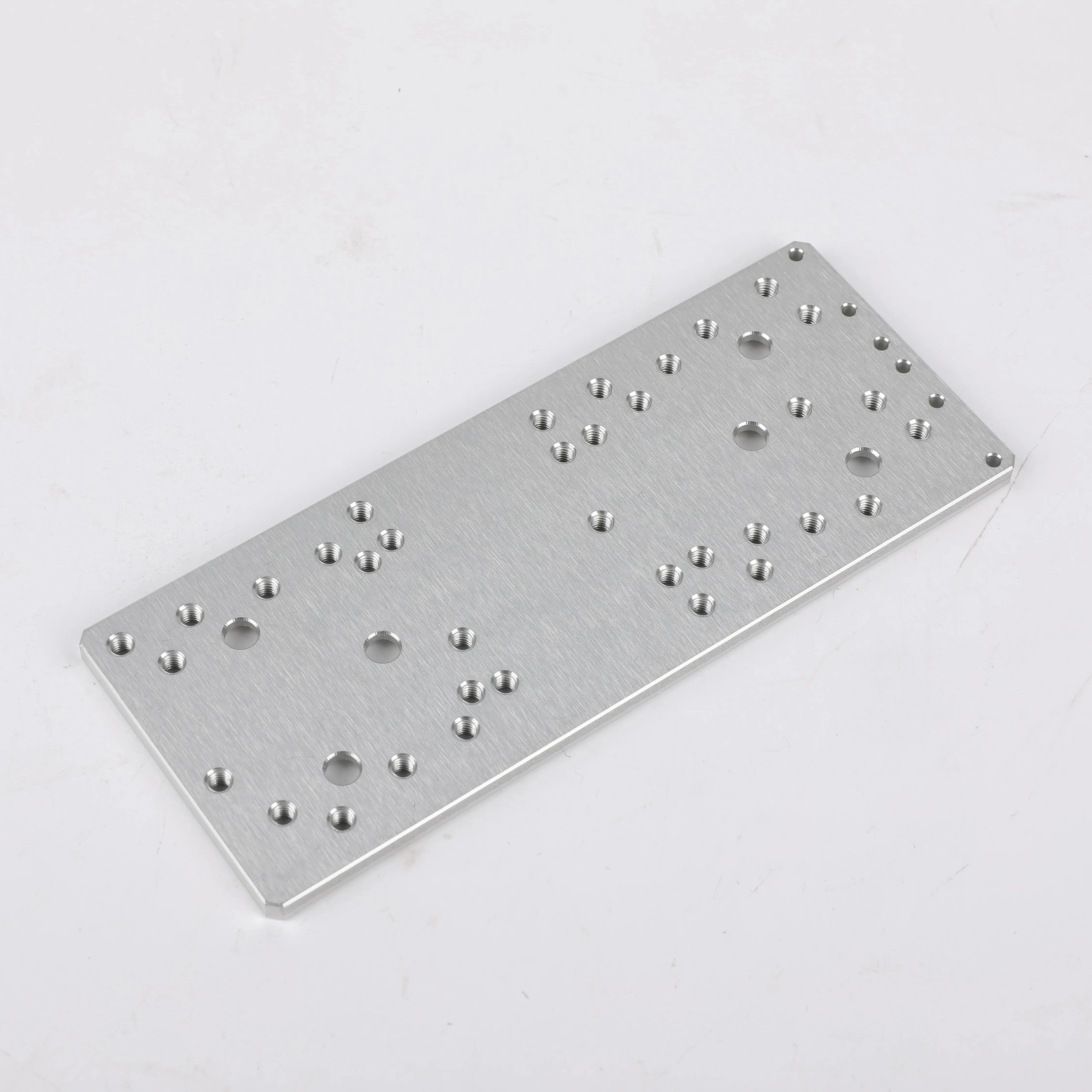

OEM CNC-dele Disse produceres generelt til slut, og når du får OEM CNC-dele, kan de potentielt være praktisk talt uopslidelige. En af de største fordele ved at bruge CNC-bearbejdning er, hvordan puslespilsmonteringsdele blev, da de spyttede ud! Med andre ord er det usandsynligt, at alle de produkter, der er fremstillet af disse materialer, går i stykker eller nedbrydes hurtigt.

Hvis du har haft sådan et legetøj, der gik ud af drift meget hurtigt efter at have leget med det. Det kan betyde, at den ikke er konstrueret af kvalitetsmaterialer. Hvis det på den anden side var dit helt eget legetøj med OEM CNC-dele, selvom dette ville være af meget højere standard og have større holdbarhed som resultat. Det er grunden til, at dele af høj kvalitet skal bruges på fabrikker, der producerer sådant legetøj eller produkter.

Mere end 14 års erfaring med oem cnc dele og komplet bearbejdningsudstyr, som inkluderer CNC fræsningsslibemaskine, CNC drejebænk, EDM, trådskæring og mere. Vi er den eneste virksomhed med en klar fordel for produkter, der er multi-processer.

Vi har et højt kvalificeret indkøbsteam samt et stort lager af leverandører til standarddele. Vi har også oem cnc dele varme- og overfladebehandlinger.

Vi har professionelle designingeniører til at oem cnc dele vores teknologi. Vores designere er dygtige til mekanisk design. Nogle af vores designere har mere end 20 års erfaring med design. De har blandt andet været involveret i procesforbedring, armaturdesign og udstyrsdesign.

OEM cnc dele kvalitetskontrol opnås gennem fuld deltagelse. Kvaliteten opretholdes gennem hele processen, begyndende med tidlig advarsel om kvalitet gennem det endelige produkt. Produkttestningen er opdelt mellem råstoftests til forarbejdning og den endelige test. Vores testudstyr er ekstremt omfattende. Det omfatter CMM-projektorer, højdemålere, projektorer, hårdhedstestere, spektrometre osv. Vi har en række udenlandske og indenlandske finansierede virksomheder. Vi har også bestået de forskellige lag af revisioner.