Tässä opetusohjelmassa näytämme sinulle kuinka helppoa on rakentaa oma CNC-reitittimesi minimaalisilla työkaluilla! Se saattaa kuulostaa aluksi hieman vähemmän helpolta, mutta luota minuun, se on helpompaa kuin miltä se kuulostaa. Osoittautuu, että jotkin asiat vaativat vain kärsivällisyyttä, vähän mielikuvitusta ja oikeaa tukea. Joten aloitetaan! Alla kerron yksityiskohtaisesti kuinka rakentaa DIY CNC -reititin alusta alkaen 10 yksinkertaisessa vaiheessa.

Aloita laatimalla materiaaliluettelo tälle projektille. Askelmoottori sen siirtämiseen, karamoottori, joka pyörii ja leikkaa, sarja poranteriä, jotta voit tehdä reikiä reitittimelläsi, sekä joitain laakereita kaiken sujuvaan toimintaan, mukaan lukien ohjauskortti, joka toimii kuten reitittimiemme aivot. Ja muutama muu osa, jotka ovat luultavasti helposti löydettävissä mistä tahansa kunnollisesta rautakaupasta. Tarkista aina, mitä sinulla on kotona ennen kuin lähdet ulos, eikä sinun tarvitse koskaan ostaa mitään!

Tässä vaiheessa suunnittelet CNC-reitittimesi. Tämä on todella hauska osa. Virtuaalinen reititin: Voit luoda reitittimesi 3D-mallina tietokoneohjelmien, kuten SketchUpin, avulla. Sinun tulisi kokeilla muutamalla eri mallilla nähdäksesi, mistä tyypistä pidät eniten ja mikä on toimivin elämäntyyliisi. Päätä, miten CNC-reitittimesi tulee rakentaa ja mitä sen on toimittava. 3.

Kun olet valmis, leikkaa kehyksen osat. Runko on CNC-reitittimesi vahvin osa ja se todennäköisesti määrittää kuinka tarkka tämä asia voi olla, korjataan se! Leikkaa osat: Palat voidaan leikata palapelillä tai käsisahalla. Kun olet leikannut ne, tee kaikki reunat sileiksi hiekkapaperilla, jotta ne ovat turvallisia käsitellä ja sopivat siististi yhteen.

Vain tehdä asioita hyvin mielenkiintoista. Kehyksen kokoaminen Aloita kehyksen valmistus. Kiinnitä osat yhteen ruuveilla tai hyvällä puuliimalla. Varmista, että kaikki on kohdistettu täydellisesti ja että CNC-reitittimesi on jäykkä. Sinun on oltava harkittu tässä vaiheessa, sillä hyvä runko on perusta sille, kuinka hyvin koneesi toimii!

Ohjauskortti on pohjimmiltaan CNC-reitittimesi aivot. Se hallitsee kaikkia liikkeitä ja toimintoja. Tämä tarkoittaa, että asennuksen yhteydessä on erittäin tärkeää toimia oikein. Lopullinen suunnitelmasi tulee tänne, esimerkkinä kamppailukoukun käyttämisestä täydellä esteradalla Unityssa. Voi olla, että kyseessä on johdotus, joten ole varovainen ja varmista, että kaikki on siellä missä sen pitääkin.

Seuraava vaihe on napsauttaa laakerisarja paikalleen. Laakerit ovat metallipaloja, joiden ansiosta kara pyörii tasaisesti. Tämä on erittäin tärkeää oman CNC-reitittimesi koko toiminnalle. Voit myös voidella laakereita hieman rasvalla, jotta ne pysyvät hyvässä toimintakunnossa ja kestäisivät pidempään.

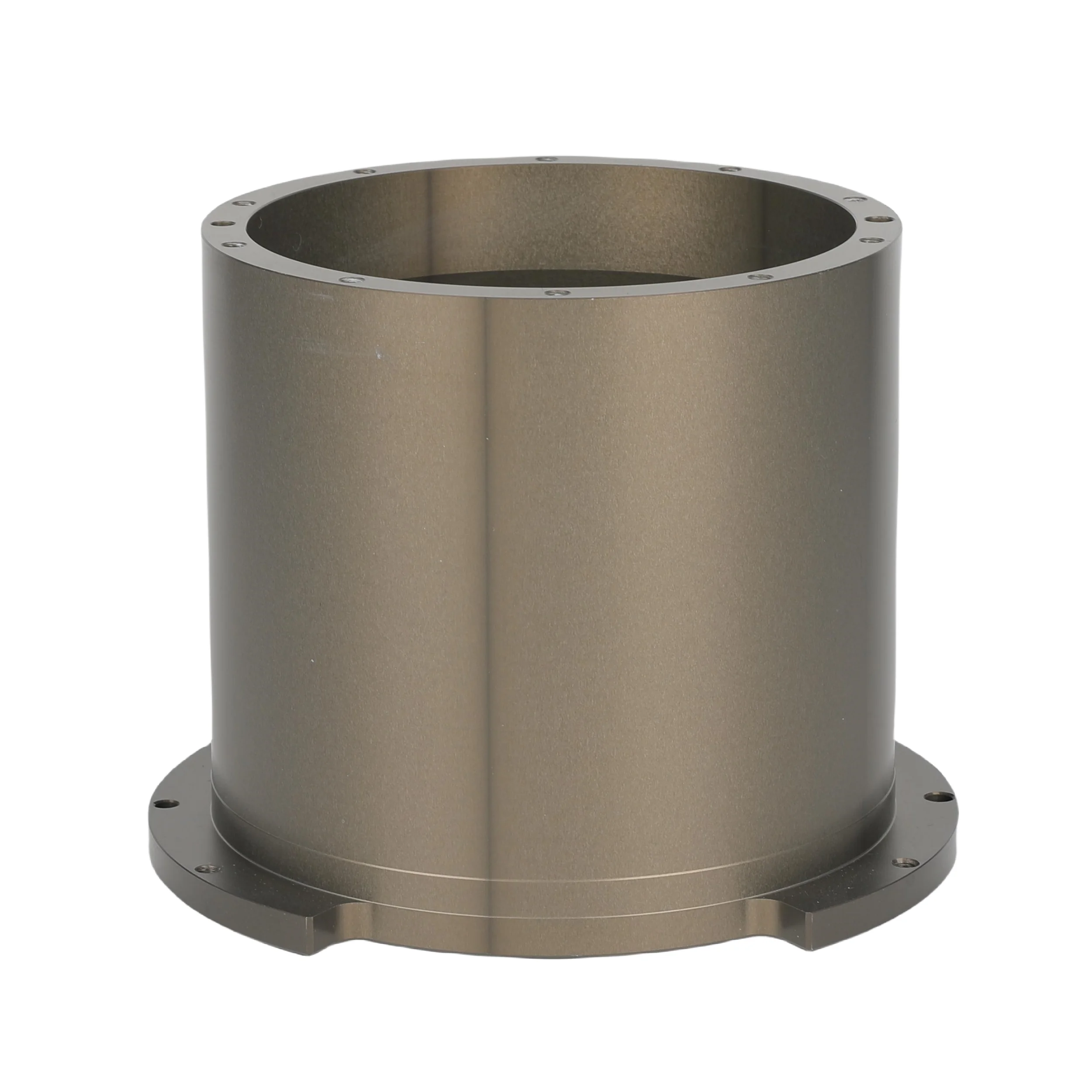

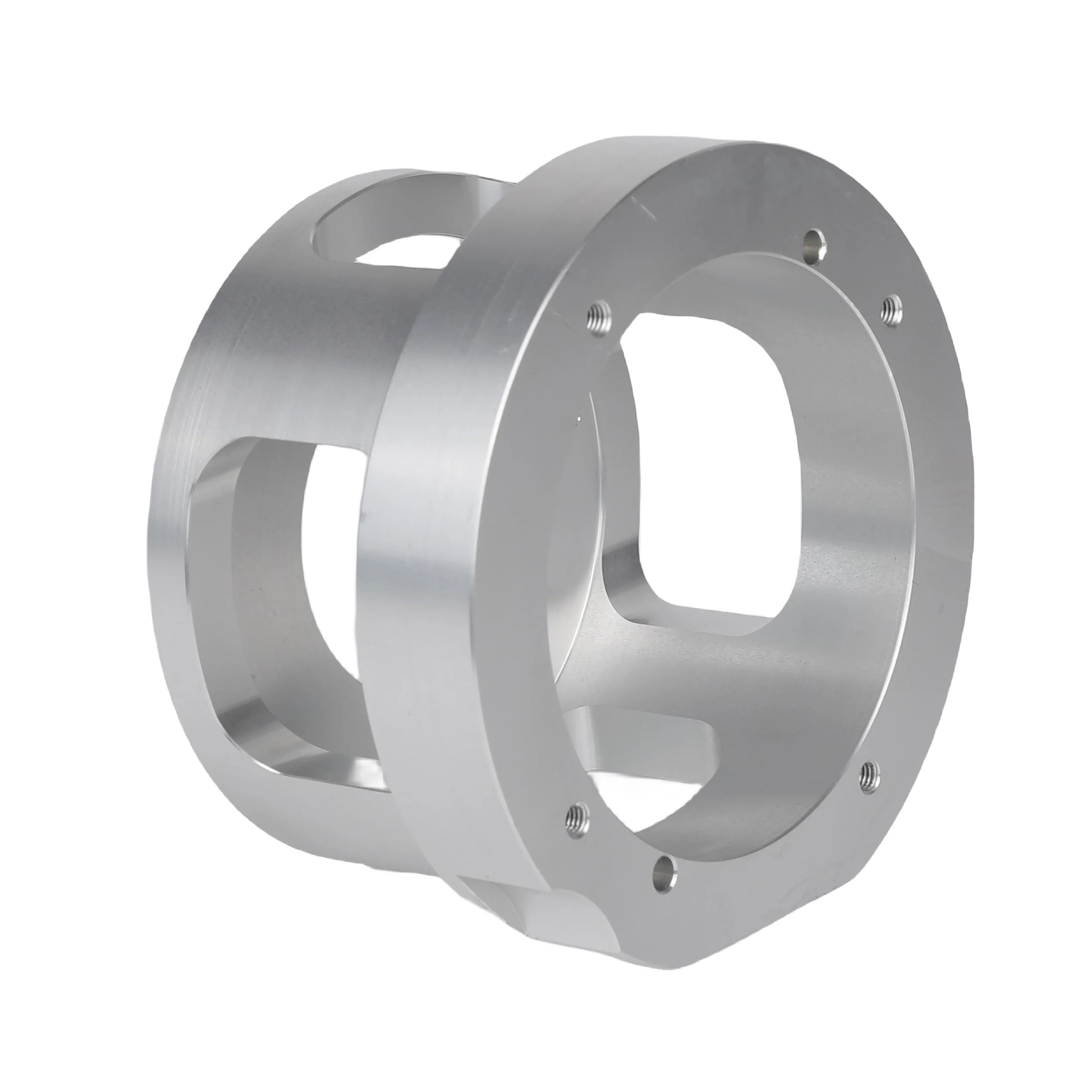

Meillä on erittäin ammattitaitoinen diy cnc -reititintiimi sekä valtava lähdevalikoima vakioosia. Ulkoistamme myös pintakäsittelyt ja lämpökäsittelyt.

Täydellinen laadunvalvonta saavutetaan täydellä osallistumisella. Alusta alkaen laadun ehkäisystä lopputuotteeseen, noudatamme tiukkaa laadunvalvontaprosessia. Tuotetestaus jakautuu raaka-ainetestaukseen, prosessoinnin testaukseen ja lopuksi testaukseen. Testauslaitteistomme on myös erittäin itse tehty cnc-reititin, päävarusteisiin kuuluvat CMM-korkeusmittari, projektori, kovuusmittari, spektrometri ja muut vastaavat laitteet. Olemme kumppani useiden kotimaisten ja ulkomailla rahoitettujen yritysten kanssa. Olemme myös läpäisseet heidän auditointinsa eri tasoilla.

Meillä on enemmän kuin itse valmistama cnc-reititin vuosien kokemus käsittelystä ja täydelliset työstökoneet, mukaan lukien CNC-jyrsintä, CNC-sorvaus, hiomakone EDM-langanleikkaus jne. Moniprosessilaitteet ovat vahvuutemme.

Kokeneet suunnittelijat tukevat itse cnc-reitittimeämme. Suunnittelijoillamme on kokemusta mekaanisen suunnittelun alalta. Joillakin on yli 20 vuoden kokemus suunnittelusta. He ovat työskennelleet prosessien parantamisessa ja kalusteissa sekä laitesuunnittelussa ja paljon muuta.