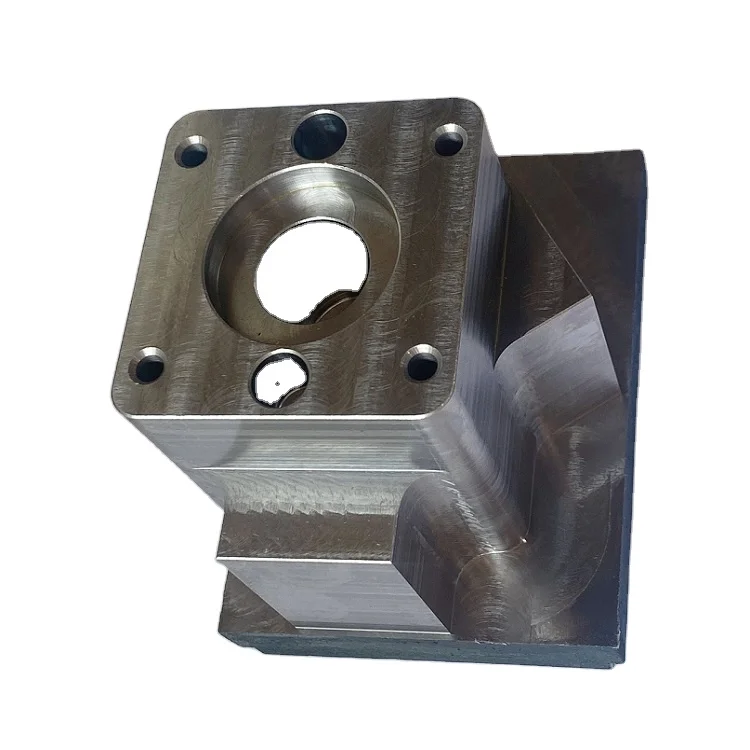

ЦNC шугаман бичгийн машин нь эргүүлэгтэй цагаан хэсэг болон эргүүлэгтэй спindle-г агуулдаг, энэ нь дундаж хувьд ихэвчлэн ашиглагддаг хэсэг юм. Тэд нь шугаман бичгийн машин нь зөвхөн зөв ажиллахад тусалдаг. Цагаан хэсэг болон спindle байхгүй бол ЦNC шугаман бичгийн машин ажиллахгүй. Эдгээр байхгүй бол шугаман бичгийн машин нь ажиллахгүй бөгөөд ажлын материалын дагуу зөвхөн зөв хэлбэр, хуруулах боломжгүй.

Цагаан булан (CNC цэцэн шүртний өмнөхэд байрладаг) Энд төвийн вальцыг (чухал хэсэг) бүртгэж байрлуулдаг. Төвийн валец нь загварыг ажиллуулах боломжтой байхад урд талыг дуудаж, материалыг зориулж бичигдээгүйгээр мөргөх, цэвэрлэх боломжийг олгодог. Цагаан булан нь эргэлтийн хурд өөрчлөх зорилгоор хэрэглэгдэх өөрөө гурван хувьсгалтай. Эргэлтийн хурд өөрчлөх нь материалыг илүү сайн ажиллуулахад чухал байдаг. Хэрэв бүх томоохон хэсгүүд танд хамгийн сайн хурданд ирвээс, цэвэрлэлт, мөргөлт нь чанартай болж, ихэнхээсээ тодорхой байдаг.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

CA

CA

TL

TL

ID

ID

LT

LT

UK

UK

VI

VI

SQ

SQ

HU

HU

MT

MT

TH

TH

TR

TR

MS

MS

GA

GA

CY

CY

IS

IS

BN

BN

MN

MN

MY

MY

UZ

UZ