Produzzjoni ta' Komponenti Maħluqa bil-Ġdid Servizzijiet ta' Dizajn

Mela servizzi ta' dizajn inovattivu għall-iksaġi, produtturi jistgħux jagħmlu iksaġi distinktivi u piżžetikament agradabili. Bill-uż tal-soluzzjonijiet inovattivijiet ta' dizajn, jinkriju idejji li jkunu mhux biss possibbli b'mod li jkunu reċenti trid metodi kif isessjonijiet ta' brainstorming jew skizzar u prototipar. Per esempju, l-użu ta' proċessi ta' manifattura addittivja kif il-printja 3D ġammut tikkonvertin ir-prototipar offrendu provveditori ta' servizzi ta' dizajn espert biex jprodutu soluzzjonijiet ta' iksaġi b'viċess aktar sveli.

Iservizzi ta' dizajn għall-iksaġi jista' jiffrodu nuovi sentiery abbażi permezz tal-innovazzjoni tal-materiali kif kompozitijiet metaliku, plastika u karbon fiber. Ma jkollhomx konkurenza meta parti tagħfu jkunu jidheru iksaġi li jgħodu effett tagħha kif il-pes leggeri, forza u rigidiċità li ma jkunu disponibbli fl-iskujjetiehem.

Id-dizajn u l-implimentazzjoni ta' servizzi għall-funktjarju awtomatiku fil-cloud privatu, u l-ġestjoni integrali widin piattaforma centralizzata

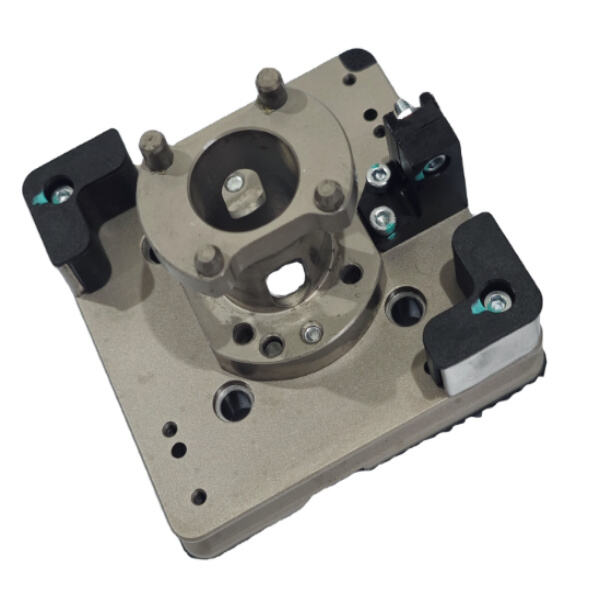

L-użu ta' servizzi ta' disegn tal-fiksa professionali għall-bidu produttiv għalbix aħjar l-efiċjenza. Mġarrba u miżjur b'sofra dettaljati biex jikkoncentraw fuq id-disegn tal-fiksa li jgħinu fl-prezizzjoni kif ukoll fil-riproduzzjoni, li huma komponenti essenzjali fit-triqta tal-manufattura. F’kwalunkwe waqt passat, jekk jogħġbok tista' tħassar servizzi ta' disegjn tal-fiksa għall-linja tal-fabbrika, dan jrid jistudja kull aspettu tal-produzzjoni biex jagħmlu identifikazzjoni tal-punti bottiglia u tagħti possibbli mill-ħaddijiet. Liġġi, provveditur tal-servizz jista' jipprovdja fiksa biex jimmel il-veloċita' tal-operazzjoni u jriduċi it-tempi ta' inaħħar li jirrisultaw fis-sa tan-nifs ir-ritmo produttiv.

Ħafna, is-servizzi ta' disegn tal-fiksa jiġuru ma' riroduzzjoni tal-disegni fuq partiti produttivi multipli. Dan japplika għal produzzjoni ta' fiksa li provveduri ta' servizz jidevloppaw għall-użu ripetut fuq runji tal-manufattura multipli fejn ma tkunx tista' tikteb retooling.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

CA

CA

TL

TL

ID

ID

LT

LT

UK

UK

VI

VI

SQ

SQ

HU

HU

MT

MT

TH

TH

TR

TR

MS

MS

GA

GA

CY

CY

IS

IS

BN

BN

MN

MN

MY

MY

UZ

UZ