Uitstekend kwaliteitsmanagement

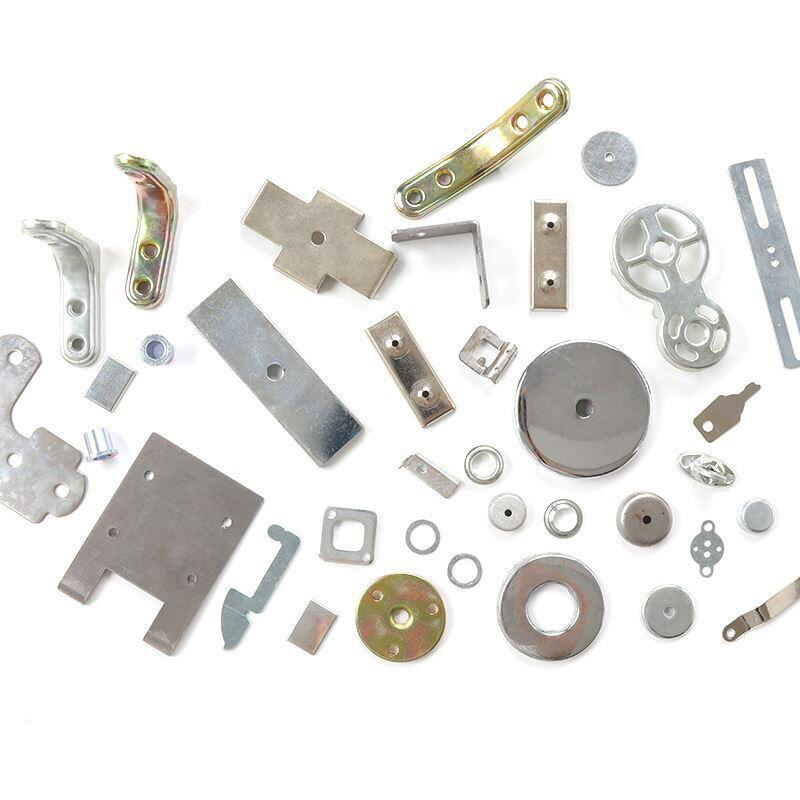

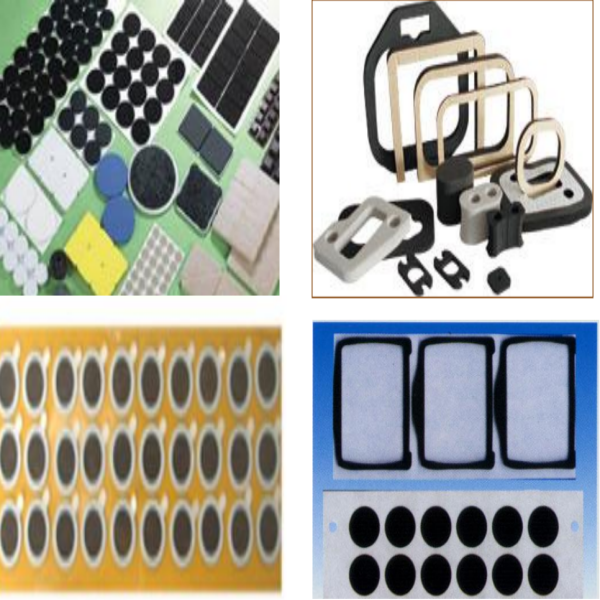

Volledige kwaliteitscontrole wordt bereikt door volledige betrokkenheid. Vanaf het begin, kwaliteitspreventie tot het eindproduct, volgen we een strikt kwaliteitscontroleproces. Het testen van het product is onderverdeeld in het testen van grondstoffen, het testen van verwerking en ten slotte het testen. Onze testapparatuur is ook zeer Cnc-machineonderdelen, de belangrijkste apparatuur omvat CMM-hoogtemeter, projector, hardheidsmeter, spectrometer en andere dergelijke apparatuur. We zijn een partner van veel binnenlandse en buitenlandse gefinancierde bedrijven. We hebben ook hun verschillende lagen van audits doorlopen.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NEE

NEE

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

CA

CA

TL

TL

ID

ID

LT

LT

UK

UK

VI

VI

SQ

SQ

HU

HU

MT

MT

TH

TH

TR

TR

MS

MS

GA

GA

CY

CY

IS

IS

BN

BN

MN

MN

MY

MY

UZ

UZ