Launching, the OEM Custom Stamping Bending Laser Cutting Folding Aluminum Stainless Steel Chassis Parts Sheet Metal Processing. This premium item is essential and useful in steel sheet processing technology, making it the right solution for any task that demands accuracy and durability.

Built from top-quality materials such as metal and stainless aluminium, Aitemoss' Chassis Parts Sheet Metal Processing was created to withstand the harshest of surroundings. Whether you are looking to make a customized framework for your vehicle or require precision-crafted items for your commercial equipment, this is the perfect option for you.

It is the best option for any professional or DIY task featuring its advanced design and cutting-edge technology. Its sleek and modern design will make any project rise above the crowd, while its durable construction will guarantee it can continue for a long time.

The Aitemoss brand prides itself on its dedication to quality and consumer satisfaction. Their group of specialists works tirelessly to make sure their products and services meet up with the greatest requirements, so you can ensure that you're getting the finest of the quality. Furthermore, their OEM modification choices permit you to produce the suitable item that is ideal to your unique requirements.

From starting to end, this was made with the consumer in mind. Their easy-to-use interface guarantees a smooth and stress-free experience while their comprehensive support guarantees that the concerns or issues are quickly and effectively addressed.

Whenever you are looking for a reasonably limited sheet steel processing solution, look absolutely no further than Aitemoss. Making use of their expertise and dedication to quality, you can trust that you will be having the most beneficial item. Order now and experience the Aitemoss difference for yourself!

What we do?

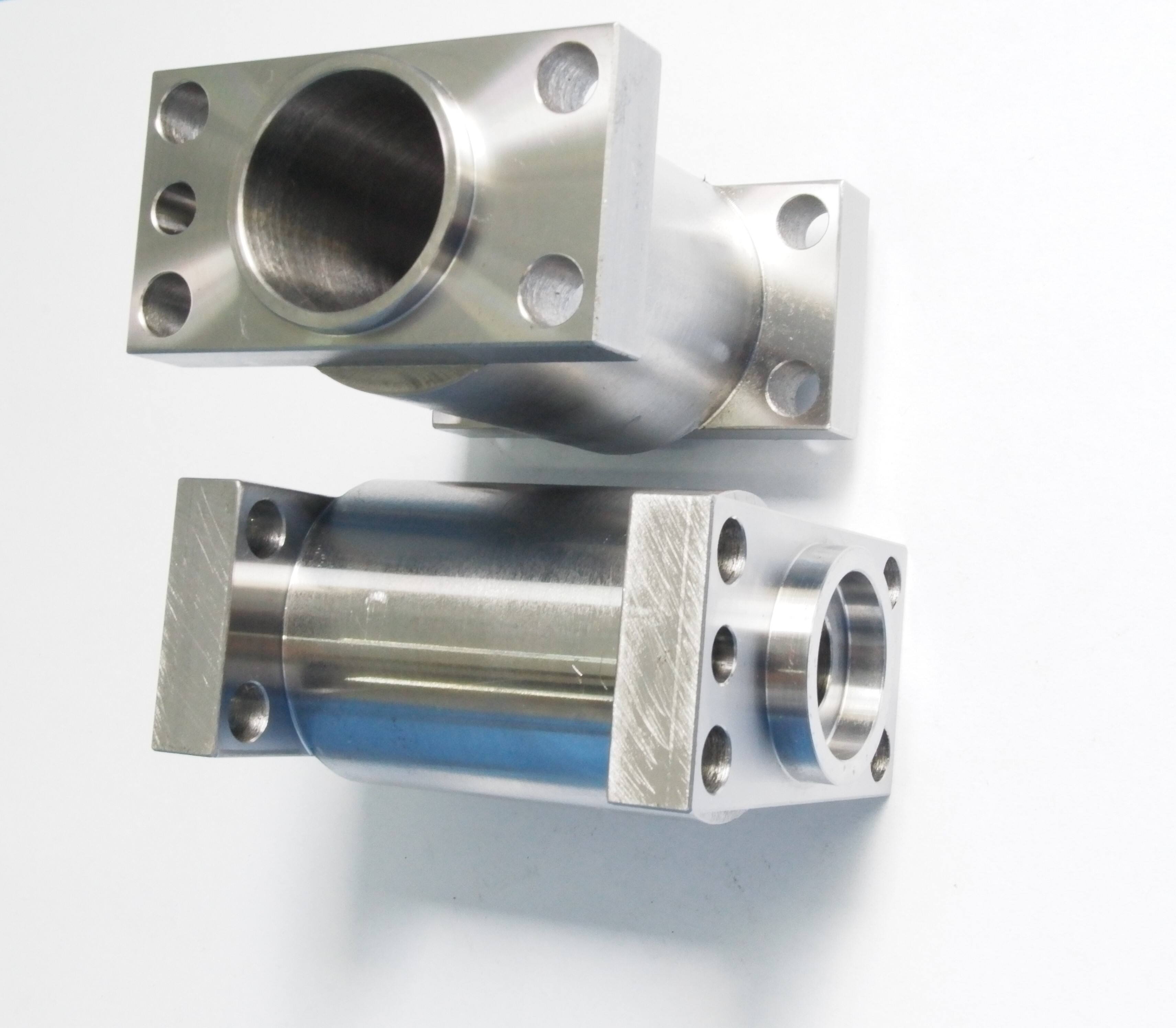

We customize according to customer drawings or samples

1. We promise: All the parts from our company have no sharp edge. All dimensions are controlled according to your drawings. Every product will be fully inspected and carefully packed to prevent the bump and rust in transit.

2. The craftsmanship of all parts we machined is controlled rigorously, every product has its own process card and process chart.

3. Our quality inspection procedure is quite strict. It must be self-inspected during production. We have flow and professional inspectors with over 10 years experience.

4. Each size of product must be tested one by one after completing production and provide quality report.

5. The most important point, we are the entity factory, not trading company. Price is the composition of the actual product

quality price. Quality can be guaranteed more controllable higherly than trading company. The price is competitive, at least

reducing the trade company's service fee.

WE ARE ONE OF SUPPLIERS OFBOSCH AND SCHAEFFLER, WHICH ARE WORLD FAMOUS COMPANIES. WE CAN SUPPLY HIGH-CLASS QUALITY AND SERVICE.

|

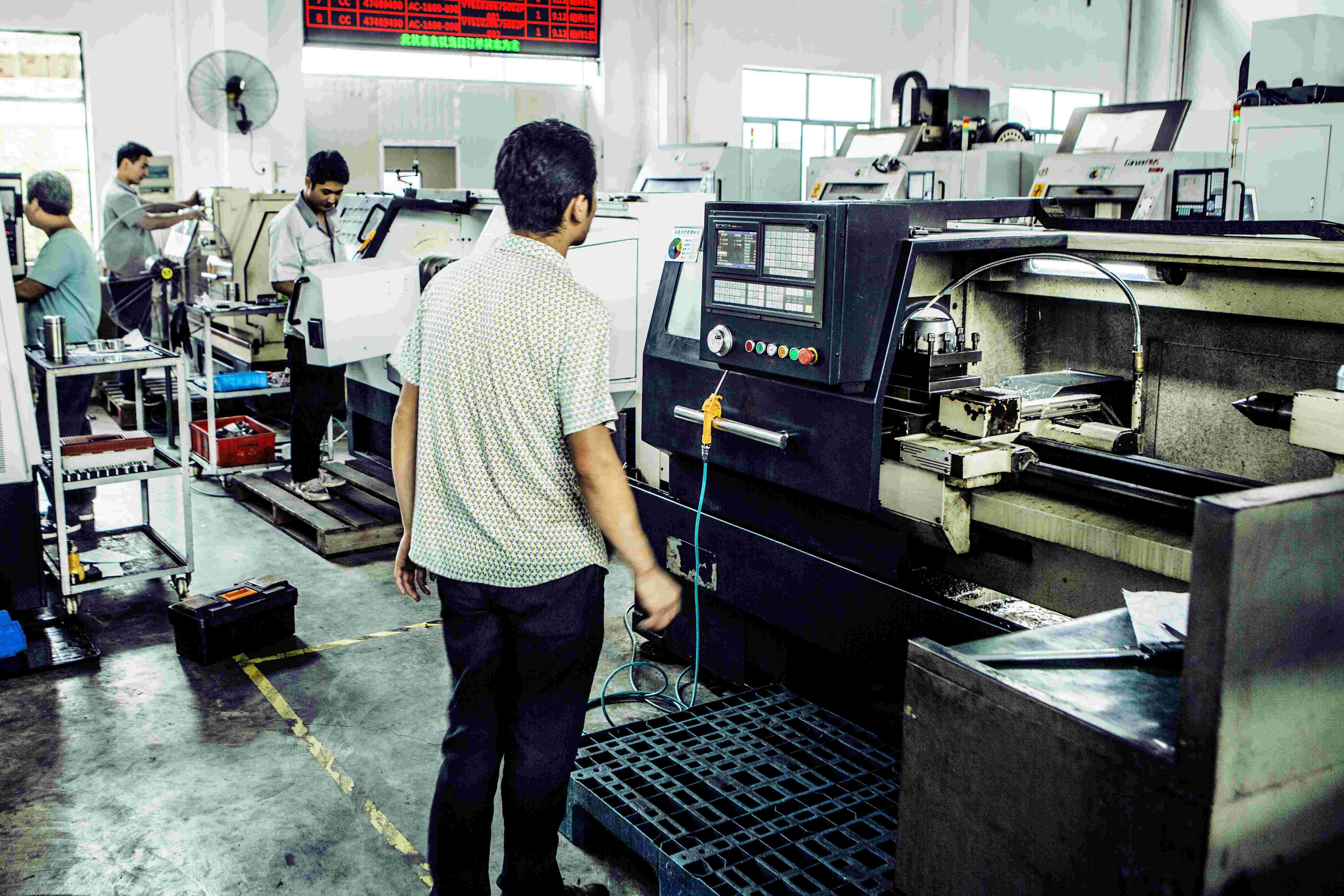

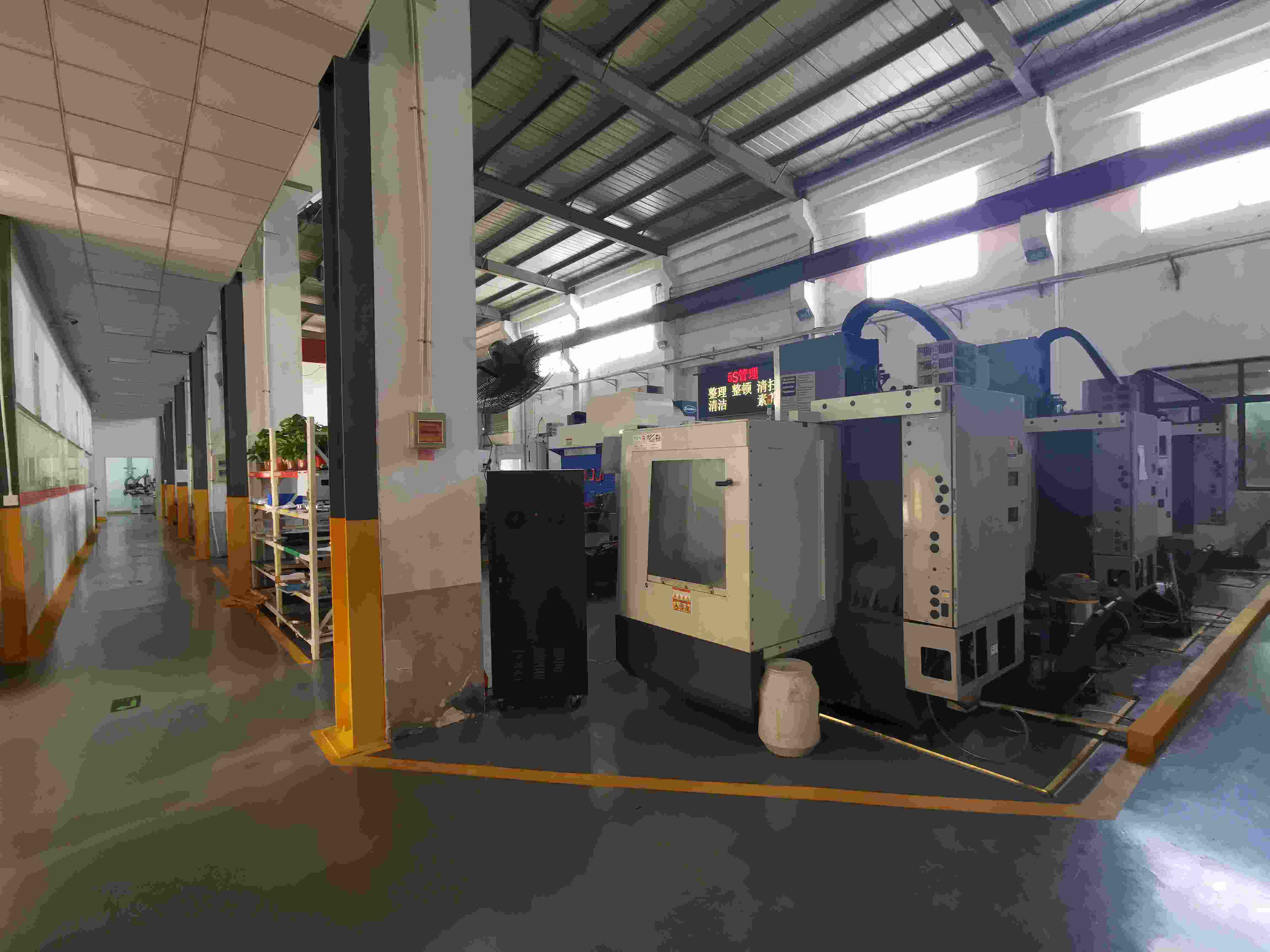

Machining Equipment

|

Machining Center/ CNC Lathes/ Grinding Machines/ Milling Machines/ Lathes, Wirecuts

machines/ Laser Cuts machines/ CNC ShearingMachines/ CNC Bending Machines/ etc

|

|

Processing

|

Turning/ Milling/ Drilling/ Wire EDM/ Welding/ Casting/ Forging/ Assembling/ etc

|

|

Tolerance

|

+/-0.005mm

|

|

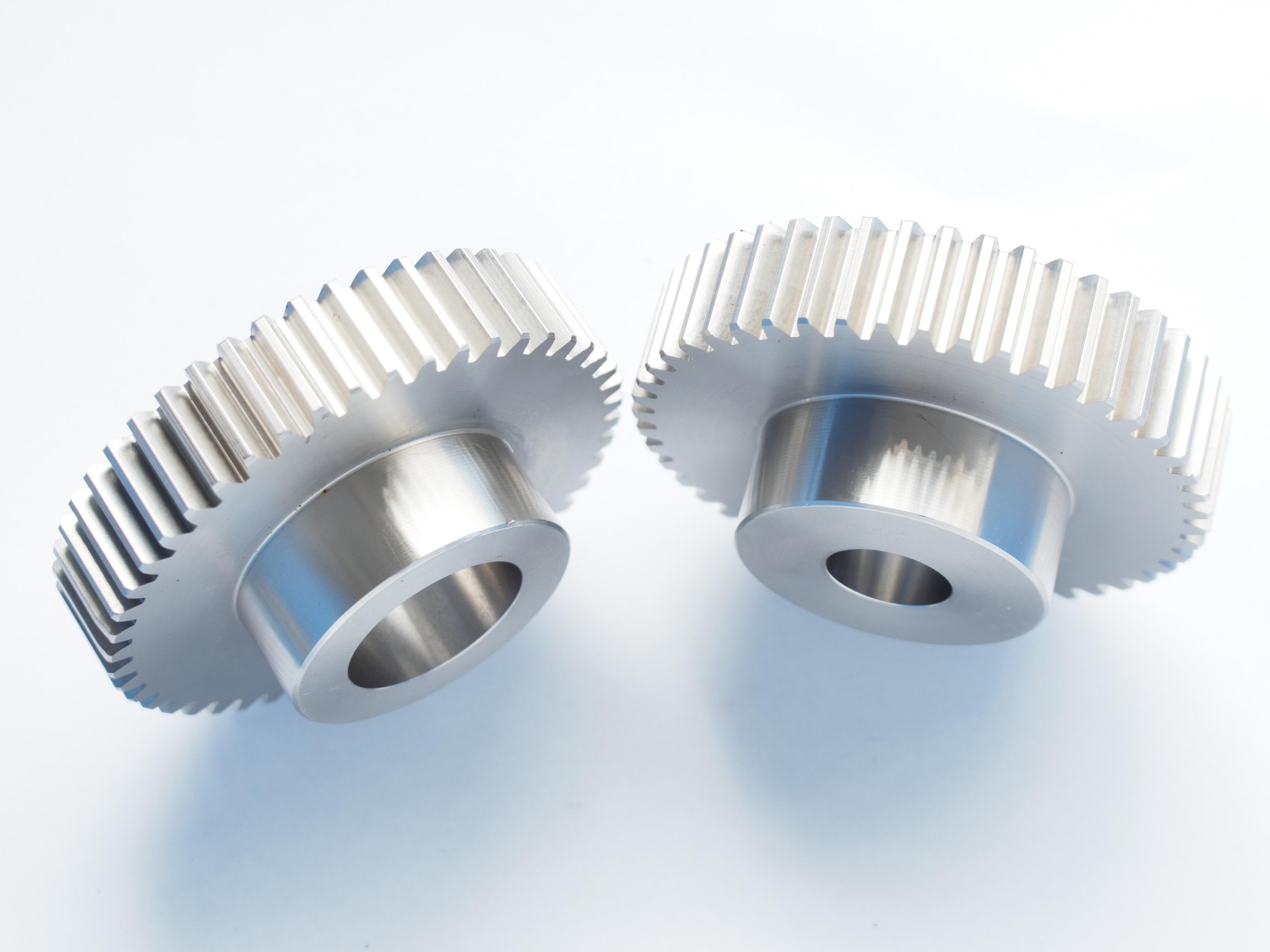

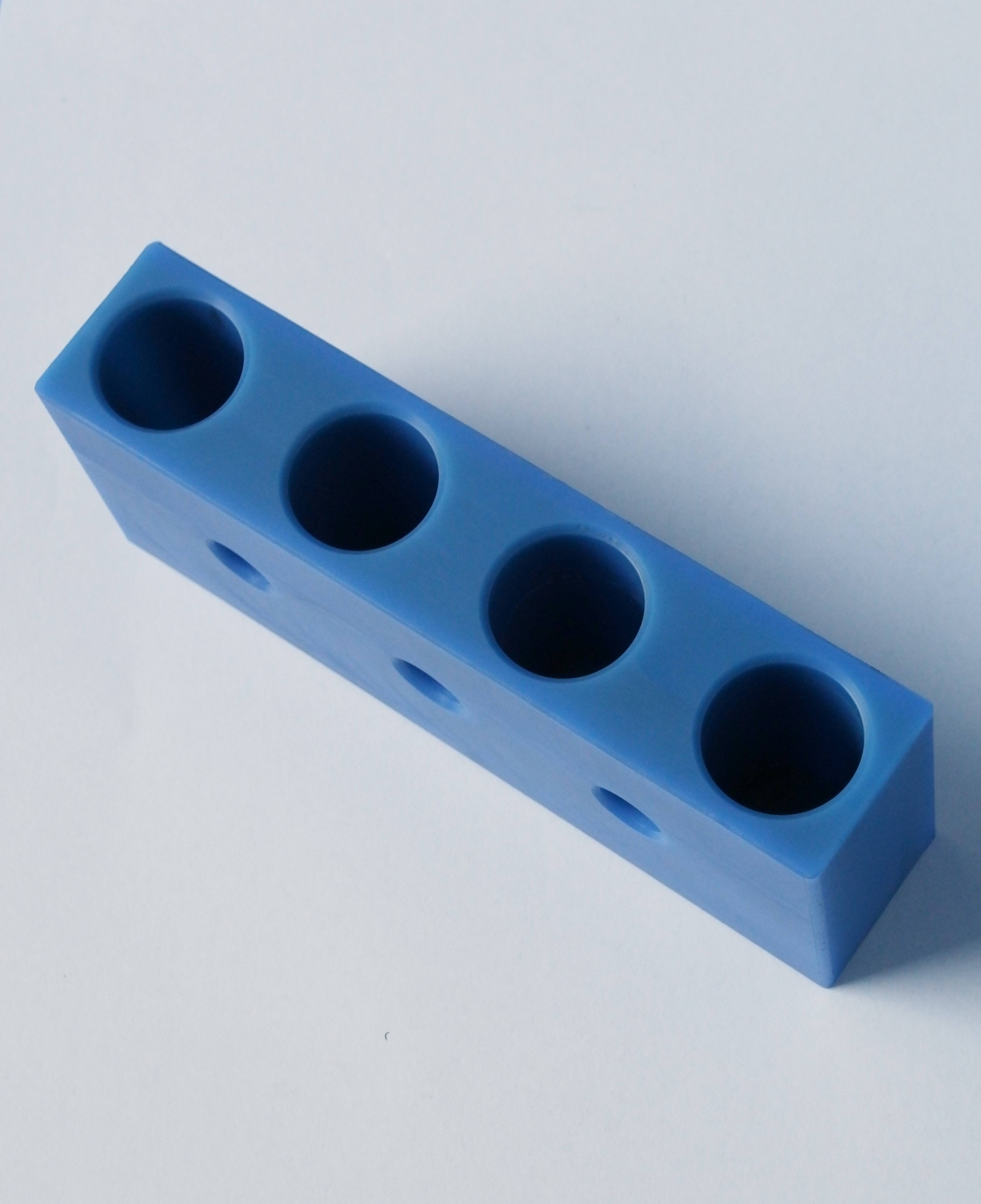

Materials

|

Aluminum/ Copper/ Stainless steel/ Ball bearing steel/ Abrasive tool steel/ Engineering

plastic/ Nylon/ etc

(If you require any other materials, please contact us to discuss.)

|

|

Surface Treatment

|

Blacking/ Polishing/ Anodizing/ Chrome plating/ Zinc plating/Nickel plating/ Chrome

plating/Ion nitriding/ tinting/ Titanium nitriding/ etc.

|

|

Product's Design

|

Customized as customers’ drawings or samples.

|

|

Inspection tooling

|

tool microscope/ digimatic micrometer/ inside micrometer/ dialgage/ electronic digital

display caliper/ automatic height gauge/ precision level 2 detector/

00 levels of marble platform/ ring gauge/ etc.

|

|

QC System

|

100% inspection according to the MIL-STD-105E, ANSI ASQC Z1.4, ABC-STD-105,

BS6001, ISO 2859, DIN 40080 before shipment.

|

|

MOQ

|

1-10pcs just for samples

|

Product Material

1) AL1060, AL6061, AL6061, AL5052

2) Steel, mild steel, SPCC3) SS201, SS303, SS304, SS316, SS316L

4) SPTE, galvanized sheet

5) Brass, copper

6) ABS, PP, PE, PC, POM

Surface Treatment

Anodized, powder coating, lacquer coating, black oxide, printing, matte, glossy, textured Size

1) According to customers' drawings

2) According to customers' samples

Drawing Format

step, dwg, igs, pdfCertificates

ISO 9001:2015 & IATF 16949

Payment Term

T/T, L/C, Trade Assurance

Title goes here.

Our factory was founded in 2010. Our team consists of highly skilled and experienced professionals, dedicated to delivering high-quality products and services to our clients. We have exported more than 20 countries like USA, Mexico, Canada, Spain, Russia,Thailand etc, and we are committed to providing our customers with professional technical support and services. Our goal is to build long-term partnerships with our clients based on trust, quality, and mutual benefit.

1. Experienced employees 2. Rich export experience in mechanical machining and design 3. Diversified products:Mutual supplier chain of industry automation 4. High quality assurance 5. Fast reaction

1.How long and how can I get quotation from your company?

We will reply you in two hours if getting detailed information during working days.

In order to quote you as soon as possible, please provide us the following information together with your inquiry.

1). Detailed drawings (CAD/PDF/DWG/IGS/STEP/JPG)

2). Materials required

3). Surface treatment

4). Quantity (per order/per month/annual)

5). Any special demands or requirements, such as packing, labels,delivery,etc.

2.Can I get samples for testing?

We can offer free samples for small parts, but for big and high-value products, samples will be charged.

3.How about the payment terms?

For new customers, we prefer to use T/T in advance. We can accept L/C, D/P for old customers.

4.If I need urgent delivery, can you help?

Of course! “Customer first” is our company philosophy. You need to tell us the delivery time when placing the order,

and we will do our best to adjust the production schedule.

5.How about the transportation?

You can choose any mode of transportation you need, sea delivery, air delivery or express delivery.

6.How about the quality guarantee?

We will make 100% inspection before packing and delivery and make sure the products 100% meet your requirements . If there is any problems during using, please tell us anytime, we will reply you in time

7.Can we sign NDA?

Sure. We never divulge any customer’s information to anyone else.

Title goes here.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.