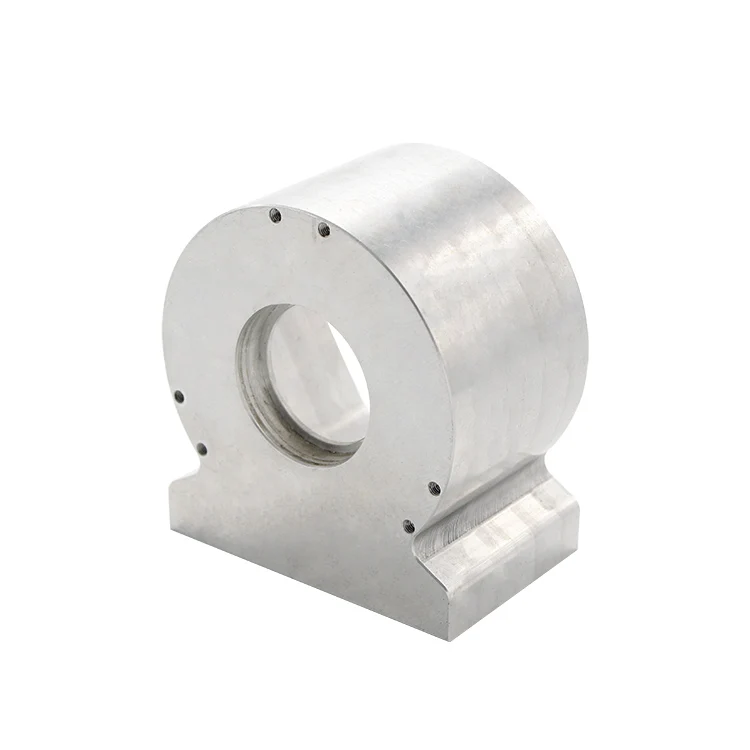

Bular orqali aniq metall hissalar yasovchi maxsus mashinaviy ishlab chiqarish jarayoni bittasi. Ushbu mashinalar CNC metall mashinasi deb ham taniladi. Ular haqida bilganimizdan eng yaxshi narsa shunda, ular tez va xatolik qilmaydi. Bu yerda ularga qanday ishlaydiganligi va nima uchun unikal ekanligi haqida gapiraman. Ular qanday ishlaydiganini va tekhnologiya keng tarqalgan maqsadlar uchun aks xatolar yo'qligi bilan metall hissalar yaratishdagi rolini o'rganing.

Bu CNC metalliy mashinalar yerdagi eng qattiq metallarni kesishi mumkin. Keyin ular uni kesishda kompyuterdan foydalanadi. Ushbu mashin kompyuter tomonidan berilgan talablarini xatolik qilmaydi bajaradi. U xato qilmaydi va tez ishlaydi. Bu muhim, chunki ushbu metalliy qismlarni yaratishda juda kam xato joyi bor - hamma narsa aniq bo'lishi kerak. Masalan, biz uni to'g'ri tushunish uchun misol olamiz, bu CNC mashinalar har bir qismni to'g'ri yaratishda bunday muammolardan xalos bo'lishga yordam beradi.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

CA

CA

TL

TL

ID

ID

LT

LT

UK

UK

VI

VI

SQ

SQ

HU

HU

MT

MT

TH

TH

TR

TR

MS

MS

GA

GA

CY

CY

IS

IS

BN

BN

MN

MN

MY

MY

UZ

UZ