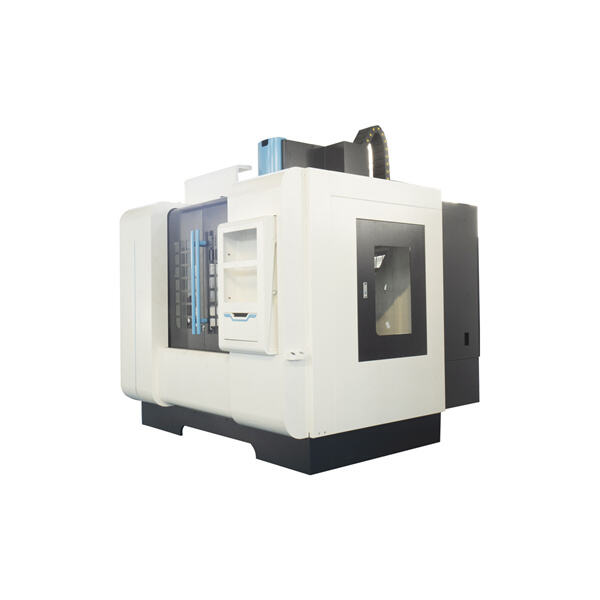

Metal CNC machines are very interesting special devices for making objects. Powered by computers Machines used to require human operation, and consequently failings were frequent. However, with custom cnc from Aitemoss, computers control the work, making it more precise and quick.

Why Metal CNC Machines are Beneficial

The good features related to Metal CNC machines Precision is probably the greatest advantage. However, the computer directs every movement of the machine so even intricate designs can be created without difficulty. In addition, they are quick working also. CNC machines can also work 24/7 without any breaks, and they have the ability to produce thousands of parts in such a little time unlike manual machining.

Metal CNC Finish: The Reason for the Force

Metal CNC machines are highly durable. They are able to cut through harder materials such as steel and titanium with ease. Making them ideal for creating parts of airplanes and cars. They are so strong that only certified professionals can handle them safely. These machines should always be operated following safety rules.

Metal CNC Machines – Perfect for Cutting Large Batches

If you need to make a lot of precise cuts in metal then CNC machines is what you should try. Their exactness is needed when things are made because they can make the most precise cuts. They can also build parts identical to each other but for industries like cars and airplanes. All parts to come off the machine will always be identical, regardless of how many it produces because all are controlled by a computer program.

Metal CNC machines have changed the manufacturing world drastically. There is still a lot for them to learn what they are allowed and capable of doing. CNC devices are sophisticated and as technology advances, ceramic cnc machining parts from Aitemoss become even more powerful with detailed design capabilities. In addition, new materials are created exclusively for use in CNC machines. Now these materials are stronger and tougher than ever, enabling people to create parts that were formerly unprintable.

To sum it up, metal CNC machines are crucial to the manufacture of components. That can include accuracy, speed and power for even the most complex cut result. So, as technology advances CNC machines will continue to be cooler and cooler. These are exciting times for DIY projects, and metal CNC machines play a major role in this evolution.

Metal CNC machines is a series of energy in modern day metal parts manufacturing. Metal CNC machines depend on computer programs to functional and are better known as ceramic cnc products from Aitemoss. Metal CNC machines are unlike conventional machine tools because they operate via computer programmes and reduced human error making them far more efficient than non-CNC equivalents.

One of the biggest benefits of Metal CNC machines is their precision. The computer guides every motion the machine makes so that even a complex pattern is straightforward to craft. Alongside, cnc drilling machine get praised for their rapid as well. CNC Metal Machining can be performed non-stop In contrast to man-driven machines that allows the development of a great deal however in no time.

Capabilities and Power of Metal CNC Machines

Metal CNC machines are insanely strong and cut through tough steels/ steel-tactical titanium like butter. This is what makes them so crucial for producing parts in sectors like aerospace and automotive. Since they are sturdy, Metal CNC machines necessitate the presence of trained personnel operating them strictly in line with rigid safety protocols.

Metal CNC Machines – The Perfect Solution to Mass Precision Cutting

Metal CNC Machines are ideal for high-volume, precise cutting duties. This enables them to make extremely precise cuts, which are very important in a range of manufacturing applications. Metal CNC machines are capable of creating the same part over and over again, which is essential in industries such as automotive or aerospace. Being ruled by a computer program, the parts are always made in exactly the same way no matter how many they make.

Metal CNC Machines What All They Can do for You?

This technology is transforming the manufacturing industry as there are continuous researches being made in order to discover what metal CNC machines can do. Metal CNC machines, have been evolving over time and are now capable of creating complex shapes due to the advancement in technology. Additionally, new materials are being created designed to be processed by Metal CNC machines that have better thermal properties, rigidity and improved tensile strength. This development makes even the production of parts that had hitherto been considered not feasible.

To summarize, Metal CNC machines are indispensable in some deliverance and for this purpose delicacy is improved quickly and easily with these intricate or compound layouts being manufactured. Metal CNC machines will only increase in potential as technology itself progresses, with more adaptation and development always shaping up the manufacturing industry. There are exciting times ahead with endless advancement, cnc machinery service is the face of future.

In addition to Metal cnc machine and machining equipment, we have an experienced team of purchasing and we have accumulated a vast supplier pool for standard components and outsourcing surface treatment and heat treatment.

We have more than 14 years of experience in processing as well as machining equipment that is complete that includes CNC milling, Metal cnc machine, CNC lathe EDM, wire cutting, etc. We are the only company with a distinct benefit for products that are multi-process.

The Metal cnc machine quality control is accomplished through full participation. The quality is maintained throughout the entire process, beginning with early warning of quality through the final product. The product testing is divided between raw material testing tests for processing, and the final test. Our testing equipment is extremely comprehensive. It comprises CMM Projectors, altimeters, projectors, hardness testers, spectrometers, etc. We have a variety of foreign and domestic-funded companies. We also have passed the various layers of audits.

Our technology is Metal cnc machine by professional designers. Our designers have experience in the field of mechanical design. Some of them have more than 20 years of experience in design. They have worked on process improvement and fixtures, as well as equipment design and much more.