Plastic is an incredibly versatile material that plays a major role in our everyday lives, making it present in things like toys and water bottles. But, have you ever realized what magic is done to the plastic to transform into these basic items? Now let us dig a little more into the interesting realm of Plastic Aitemoss CNC Machine!

Plastic is an incredibly versatile material that plays a major role in our everyday lives, making it present in things like toys and water bottles. But, have you ever realized what magic is done to the plastic to transform into these basic items? Now let us dig a little more into the interesting realm of Plastic Aitemoss CNC Machine!

The process of plastic machining starts with one choosing the right type as per requirements such as hardness and flexibility that can affect the way they are manufactured. The selected plastic is then cut and shaped using Aitemoss fast cnc machining.

Coolant is key, as it ensures you use oil or water during plastic machining to keep the temperature of plastics under control while being machined. This is very important as overheating can indeed cause plastic to melt or warp and also alter the quality of your print.

Advanced Plastic Machining Technology Is Revolutionizing Manufacturing

Plastic machining domain has undergone a revolutionary change with the introduction to high-end technologies. 3D printing is transforming the way we produce things, taking software written by a computer and creating printed products through plastic materials. Robotics also play a growing part in plastic machining, as robots can quickly complete tasks with precision to help increase efficiency and minimize costs.

Revealing the Advantages of CNC Plastic Machining from Custom Perspective

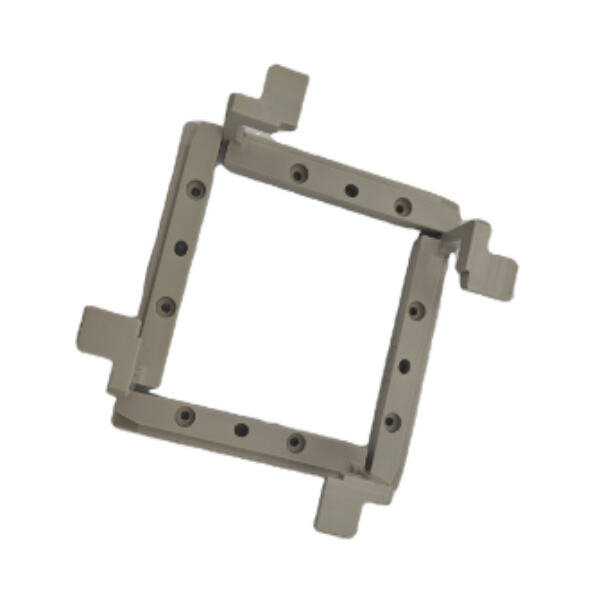

Custom CNC plastic machining offers so many benefits for custom applications. Some items that require an incredibly high degree of accuracy really benefit from its ability to make extremely accurate shapes and dimensions. The lathe machining services not only allows for very complex geometries parts to be made, but also simplify the ease to develop and create intricate shaped designs which would have been too awkward or unscheduled when bending automatics part articulation.

Predicting The Future Of Plastic Machining Innovations

One interesting new trend in plastic machining is the use of "green" materials and processes to help some companies reduce their footprint on nature. By using sustainable plastics, companies show that they are taking a step towards environmental accountability. The rising automation in plastic machining represents an outward reach towards a future where technology and robotics become pivotal within the broader manufacturing spectrum.

Plastic machining is an integral part of the manufacturing process for many products. We will deploy state-of-the-art technologies and methods that make it possible to manufacture products with a new standard of precision, efficiency, sustainability enabling the future of manufacturing using metal cnc machine.

Total quality management is achieved through participation in Plastic machining. From the early quality prevention to the more advanced product, it is a stringent quality control process. Testing of the product is split between raw material testing, the testing of processing and finally testing. Our equipment for testing is very complete, the main equipment includes CMM projector, altimeter and hardness tester, spectrometer and many more. We work with a variety of domestic and foreign-funded companies. We also have passed through their different layers of audits.

Plastic machining have more than 14 years of experience and the complete equipment for machining such as CNC milling CNC lathe, grinding machine EDM, wire cutting etc. We have a unique benefit for products that are multi-process.

We have experienced design engineers to Plastic machining our technology. Our designers are experienced in mechanical design. Some of our designers have more that 20 years experience in the field of design. They have been involved in process improvement and fixtures, as well as equipment design and much more.

In addition to automation and machining equipment, we also have a professional purchasing team, and we have Plastic machining a vast source pool of suppliers for standard parts, as well as outsourcing surface treatment and heat treatment.