Tábhacht na Seirbhísí Deil

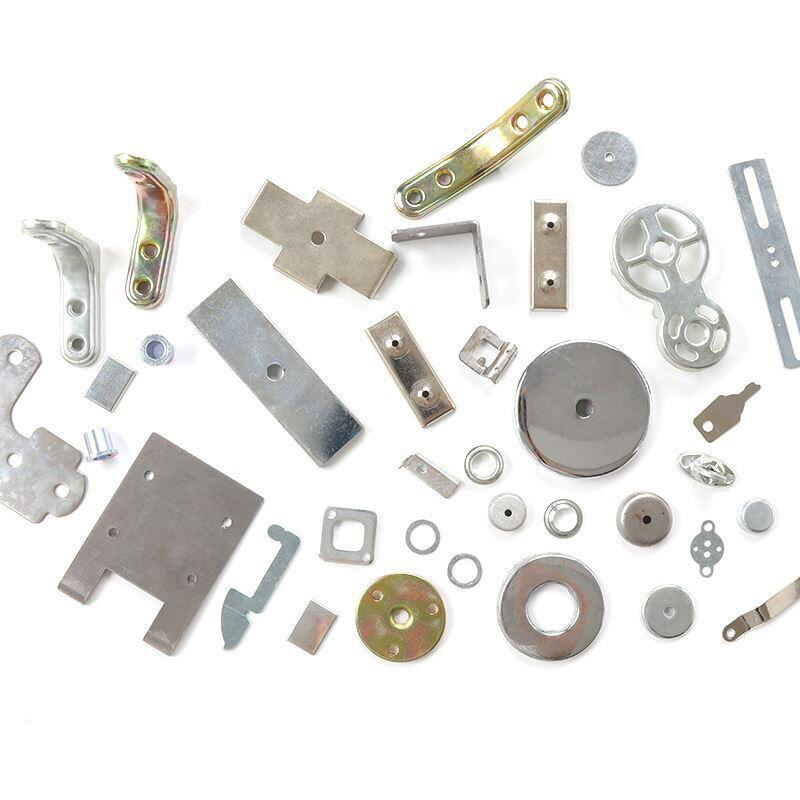

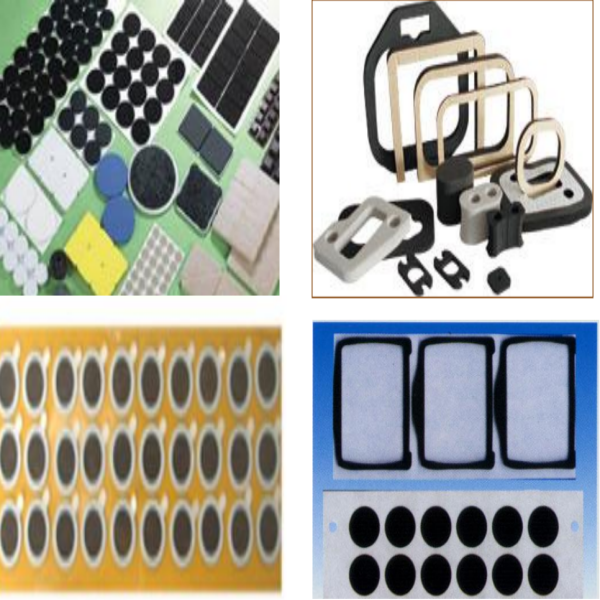

Tógtha chun ealaín a tháirgeadh thar go leor earnálacha eile, lena n-áirítear aeraspáis agus feithicleach; Déanann ár seirbhísí deil freastal ar raon riachtanas. Ligeann meaisínithe beachta dúinn páirteanna beachtais a dhéanamh go tapa agus aird a thabhairt ar mhionsonraí a bheadh dodhéanta gan é. Tá sé ríthábhachtach i dtionscail mar leictreonaic agus aeraspáis. Teastaíonn táirgí ó na hearnálacha seo atá iontaofa, éifeachtúil, marthanach agus níos daingne mar is féidir le haon locht iontu caillteanas na milliúin a chruthú agus mar sin ba mhaith leat saineolaí ceantair oibriú ar thorthaí meaisínithe go díreach an t-aschur atá de dhíth ar do ghnólacht.

Nuair a bhíonn cuideachtaí inár gcomhpháirtithe, déanann siad ár gcumas déantúsaíochta beachtas a ghiaráil agus ní dhéanaimid comhréiteach ar cháilíocht. Dearadh na réitigh shaincheaptha de réir riachtanais uathúla gach cliant, rud a ligeann dúinn gach tionscadal a fheidhmiú le fócas gan staonadh ar mhionsonraí.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NÍL

NÍL

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

CA

CA

TL

TL

ID

ID

LT

LT

UK

UK

VI

VI

SQ

SQ

HU

HU

MT

MT

TH

TH

TR

TR

MS

MS

GA

GA

CY

CY

IS

IS

BN

BN

MN

MN

MY

MY

UZ

UZ