Fordelene ved Aluminium CNC-masking

Det er mange fordeler med aluminium CNC-masking: korte leveringstider, bedre nøyaktighet og skalerbarhet av produksjonsprosjekter. Produksjonsbedrifter kan skille seg ut som innovatører og tidlige adoptere samtidig som de omfavner neste generasjons teknologier med disse 3-aksess maskin tjenester.

Vi ser mot framtida

Med videre utvikling i teknologien blir integreringen av aluminium kombinert med CNC en viktig del av hva produksjonen holder for oss i fremtiden. For å få mest mulig ut av å jobbe med aluminiumsmaterialer og opprette høykvalitetsprodukter med godt design, må produsenter være oppdatert på de nyeste CNC-utviklingene.

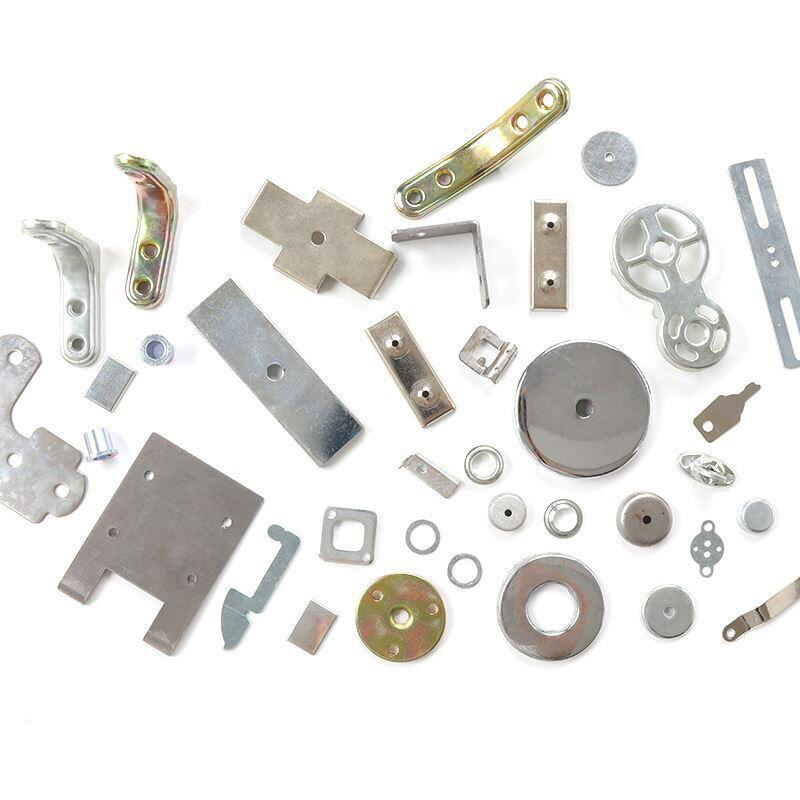

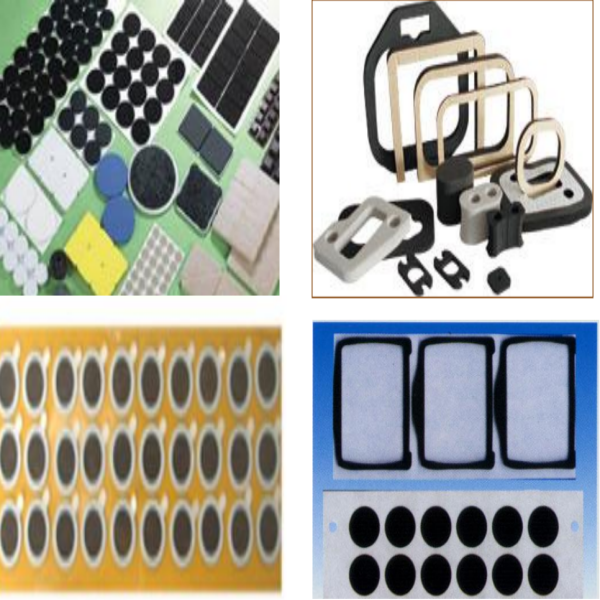

Produksjonsprosesser som involverer bruk av CNC-teknologi kan hjelpe både på kvalitet og design, fra luftfartskomponenter til fine, intrikate smykker, og la produsenter oppleve uendelig suksess mens de håndterer en alltid utviklende industri.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

CA

CA

TL

TL

ID

ID

LT

LT

UK

UK

VI

VI

SQ

SQ

HU

HU

MT

MT

TH

TH

TR

TR

MS

MS

GA

GA

CY

CY

IS

IS

BN

BN

MN

MN

MY

MY

UZ

UZ